Did you know there are over 1,000 types of capacitors? These parts are key in many devices like phones and TVs. They help electrical current flow smoothly, making sure things work right.

This guide will show you the world of capacitors. We’ll talk about how they work and the many types used today. It’s for anyone interested in electronics, from hobbyists to engineers.

Key Takeaways

- Capacitors are essential electronic components that store and release electrical energy

- There are over 1,000 different types of capacitors, each with unique characteristics and applications

- Capacitors are used in a wide range of electronic devices and circuits, from power supplies to audio equipment

- Understanding the different types of capacitors is crucial for designing and troubleshooting electronic systems

- Choosing the right capacitor for a specific application requires consideration of factors such as voltage rating, capacitance, and temperature tolerance

Understanding Capacitors: Basic Principles and Functions

Types of Capacitors – Capacitors are key in electronic circuits. They store and release electrical energy. Knowing how they work is important.

How Capacitors Store and Release Electrical Energy

Capacitors store electrical charge. When a voltage is applied, they fill with charge. This charge can power other parts of the circuit.

Key Components and Construction

A capacitor has two metal plates and a dielectric in between. The dielectric stops current flow. The plates’ size and the dielectric’s properties affect how much charge it can hold.

Role in Electronic Circuits

Capacitors are crucial in circuits. They filter signals, smooth voltages, and help with timing. Different types, like ceramic capacitors and electrolytic capacitors, serve various needs.

Learning about capacitors helps us understand their role in electronics. It aids in designing and fixing electronic systems.

Types of Capacitor: Fixed vs Variable Capacitors

There are two main types of capacitors: fixed and variable. Knowing the difference helps you pick the right one for your project.

Fixed Capacitors always have the same value. They’re great when you need a steady value. Film capacitors and mica capacitors are common fixed capacitors.

Variable Capacitors let you change the value. This is good for tuning circuits or adjusting frequencies. They’re often in audio and radio gear.

| Fixed Capacitors | Variable Capacitors |

|---|---|

| Constant, unchangeable capacitance value | Adjustable capacitance value |

| Ideal for applications requiring precise, stable capacitance | Useful for tuning and adjusting circuit parameters |

| Examples: film capacitors, mica capacitors | Examples: variable capacitors used in audio and radio equipment |

“Capacitors are essential components in electronic circuits, playing a crucial role in storing and releasing electrical energy.”

Types of Capacitors – Understanding fixed and variable capacitors helps in designing projects. It’s key to know their uses and features.

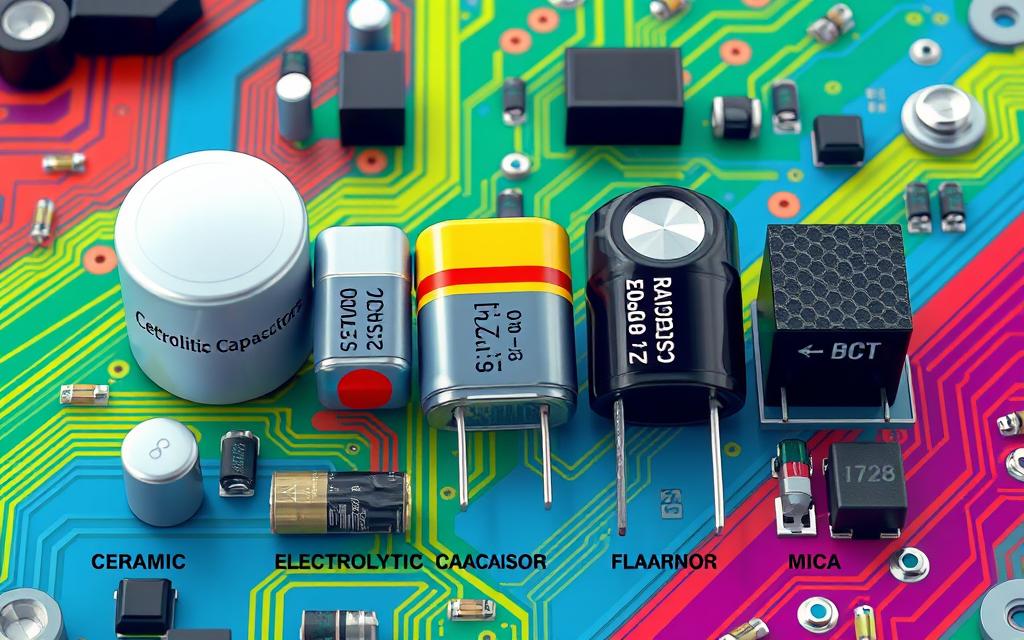

Common Types of Fixed Capacitors in Modern Electronics

In today’s world, many types of fixed capacitors are key in electronics. They help power and control devices. Each type, like ceramic, electrolytic, film, and tantalum, has special features for different needs.

Ceramic Capacitors and Their Applications

Ceramic capacitors are very common in electronics. They have high capacitance, are small, and work well at high frequencies. They’re used in many places, like in filters and radio circuits.

They can handle high temperatures and voltages. This makes them great for power supplies and motor drives.

Electrolytic Capacitors: Advantages and Limitations

Electrolytic capacitors have a lot of capacitance in a small space. They’re good for big capacitance needs, like in power supplies and audio gear. But, they don’t last as long because their electrolyte dries out.

They also have a higher resistance than other capacitors. This can be a problem in circuits that need to work at high frequencies.

Film Capacitors in High-Frequency Applications

Film capacitors are great for high frequencies and lose less energy. They’re used in power electronics and radio circuits. They come in different materials, each with its own benefits and drawbacks.

Tantalum Capacitors for Specialized Uses

Tantalum capacitors have a lot of capacitance in a small space. They have low leakage and are stable over time and temperature. They’re used in portable devices and medical equipment where size and reliability matter.

Even though they cost more, they’re perfect for special needs.

| Capacitor Type | Capacitance Range | Voltage Rating | Key Applications |

|---|---|---|---|

| Ceramic Capacitors | 1 pF to 100 μF | 6.3 V to 6 kV | Decoupling, filtering, RF circuits, power supplies |

| Electrolytic Capacitors | 1 μF to 10,000 μF | 6.3 V to 500 V | Power supplies, audio equipment, electronic filters |

| Film Capacitors | 100 pF to 100 μF | 50 V to 3 kV | Power electronics, RF circuits, filtering |

| Tantalum Capacitors | 0.1 μF to 470 μF | 4 V to 100 V | Portable electronics, medical devices, aerospace |

“The choice of capacitor type depends on the specific requirements of the electronic circuit, such as capacitance, voltage rating, frequency response, and environmental conditions.”

Advanced Capacitor Technologies and Specialized Applications

Modern electronics have seen big changes thanks to new capacitor tech. We now have more than just simple capacitors. Each new tech has special uses and powers.

Supercapacitors are a big deal. They can hold and give out lots of energy fast. This makes them great for things like green energy and electric cars.

Polystyrene capacitors are also new and cool. They work well with high frequencies and stay stable in different temperatures. They’re used in things like radios and audio gear.

Paper capacitors are special for high-voltage needs. They use paper to store energy safely. This is good for things like cars and planes.

As we need better ways to store energy, capacitor tech is key. It’s helping us power our world in new ways. From green energy to space, these capacitors are changing everything.

“The future of electronics lies in the advancements of capacitor technology, unlocking new possibilities across diverse industries.”

Choosing the Right Capacitor for Your Project

Choosing the right capacitor is key for electronic projects. Capacitors vary in types of capacitor, each with its own specs. Knowing these can help your project work well.

Voltage Ratings and Capacitance Values

First, figure out the voltage your project needs. Ceramic capacitors and electrolytic capacitors have different ranges. Make sure your circuit’s voltage doesn’t exceed the capacitor’s rating.

Then, think about the capacitance value you need. This value affects how well the capacitor stores and releases energy. Pick a capacitor that fits your project’s needs.

Temperature Considerations and Tolerances

Temperature can change how a capacitor works. Some are more affected by temperature than others. Choose a capacitor that works well in your project’s temperature range.

Cost vs. Performance Analysis

When picking a capacitor, balance cost and quality. Better capacitors might cost more but offer better performance. Think about what your project needs and your budget to find the best capacitor.

| Capacitor Type | Voltage Range | Capacitance Range | Temperature Tolerance | Typical Cost |

|---|---|---|---|---|

| Ceramic | 10V to 100V | 1pF to 100μF | ±5% to ±20% | $0.01 to $0.50 |

| Electrolytic | 6.3V to 450V | 0.1μF to 10,000μF | ±20% to ±50% | $0.10 to $5.00 |

| Film | 50V to 1000V | 0.01μF to 10μF | ±2% to ±5% | $0.10 to $2.00 |

| Tantalum | 4V to 100V | 0.1μF to 470μF | ±5% to ±10% | $0.50 to $5.00 |

By looking at voltage, capacitance, temperature, and cost, you can pick the right types of capacitor for your project. This ensures your project works well and reliably.

Conclusion

The world of capacitors is big and has many types. Each type is made for different uses in electronics. Knowing about these types is key for anyone who loves or works with electronics.

When you’re making a circuit or fixing a device, picking the right capacitor is important. Look at things like voltage, capacitance, and cost. This helps make sure your designs work well and last long.

New capacitor technologies will keep coming as electronics get more advanced. Staying updated helps you pick the best capacitors for your projects. This is true for both simple projects and big industrial ones.

FAQ’s

1. What are the different types of capacitors?

There are many types of capacitors. These include ceramic, electrolytic, film, mica, supercapacitors, and variable capacitors. Also, there are tantalum, polystyrene, and paper capacitors.

2. What are the advantages and disadvantages of ceramic capacitors?

Ceramic capacitors are small and have a lot of capacitance. They work well over a wide range of temperatures. But, they can’t handle high voltages and may break down over time.

3. How do electrolytic capacitors differ from other types?

Electrolytic capacitors hold a lot of charge in a small space. They’re great for filtering and decoupling. But, they don’t last long and need to be used carefully.

4. What are the key applications of film capacitors?

Film capacitors are good for high-frequency and high-voltage tasks. They’re used in power supplies and RF filtering. They have low leakage and are very stable.

5. When would you use a mica capacitor?

Mica capacitors work well at high frequencies. They have low loss and are very stable. They’re used in RF and precise analog circuits.

6. What are supercapacitors and how do they differ from traditional capacitors?

Supercapacitors store a lot of energy. They’re used in hybrid cars and renewable energy systems. They charge and discharge quickly.

7. How do variable capacitors work and what are their uses?

Variable capacitors change their capacitance. They’re used in radio tuning and impedance matching. They’re found in radio devices.