What is Rogowski Coil?

A Rogowski coil is a type of electrical current sensor that used to measure an alternating current (AC). This coil consists of a coiled conductor (usually a flexible wire or cable) without a magnetic core.

When an AC current passes through the conductor, it induces a voltage in the coil due to faraday’s law of electromagnetic induction. For more simplicity have a short overview of faraday law

What is faraday’s law:

Faraday’s law of electromagnetic induction is named after the physicist Michael faraday, this law describes the relationship between a change in magnetic field and the induced electromotive force (EMF) in a circuit.

In simple terms, it states that when there is a change in magnetic field through a loop of wire, so it induces an electric current in that wire.

This phenomenon is the basis for many electrical devices such as generators and transformer and this Rogowski coil also.

So come Back to topic, this induced voltage is proportional to the rate of change of the current that allowing the Rogowski coil to measure high-frequency AC currents accurately.

Rogowski coils are often used in power quality monitoring, energy management systems and electrical equipment testing where precise measurements of AC current is required.

Working Principle of Rogowski coil

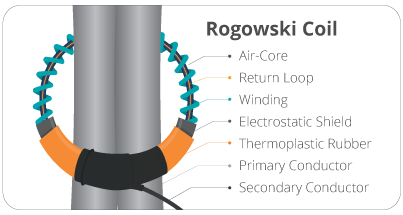

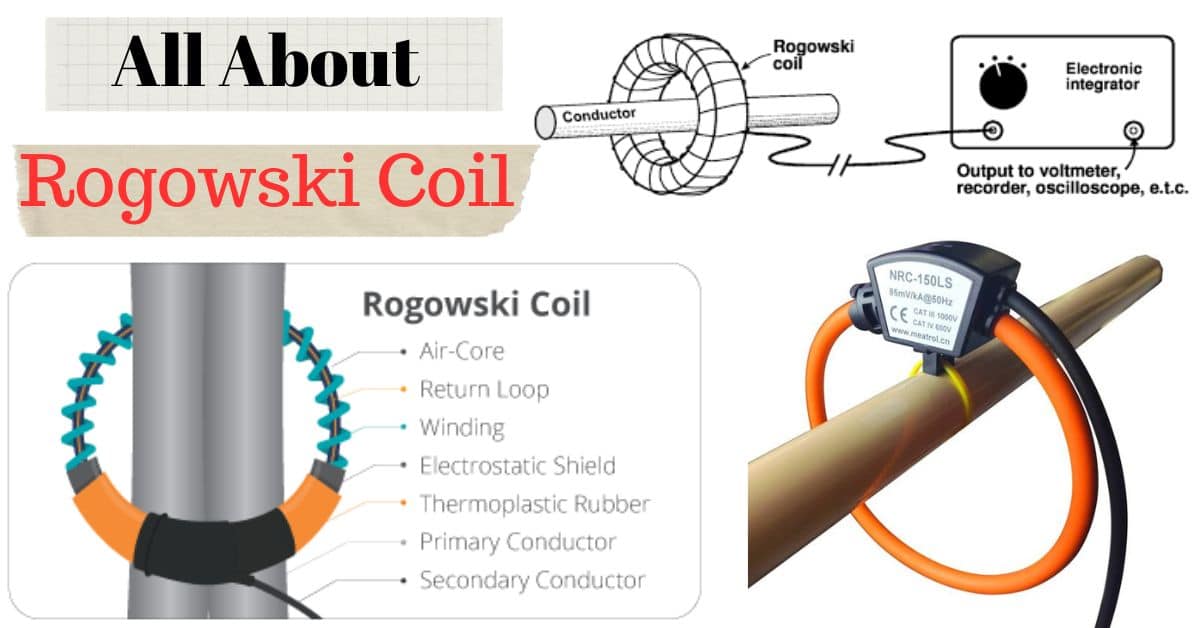

The Rogowski coil is designed as a flexible air-core coil of wire, distinct from traditional current transformers by lacking a magnetic core.

When an alternating current (AC) flows through a conductor near the Rogowski coil, it creates a changing magnetic field around the conductor.

This changing magnetic field induces a voltage in the Rogowski coil by following faraday’s law of electromagnetic induction. The magnitude power factor (pf) this induced voltage is directly proportional to rate of change of the current I the conductor.

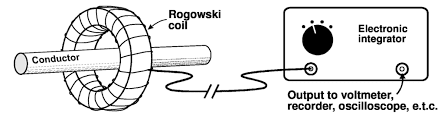

Unlike current transformer which provide a direct measurement of current, the output voltage from the Rogowski coil needs to be integrated over time to determine the total amount of current that has passed through the conductor during a specific period.

This integration process convents the voltage signal into a usable current measurement.

The following integration are the output signal from the Rogowski coil undergoes further processing using electronics or software algorithms to obtains the desired current measurements.

This processing step is essential for accurately determining the AC current flowing through the conductor.

Rogowski coil current sensor

Rogowski coil consists of a flexible coil made of wire wound in a helix shape. As we mention above when AC current flows through a conductor placed inside the coil it induced a voltage in the coil due to electromagnetic induction.

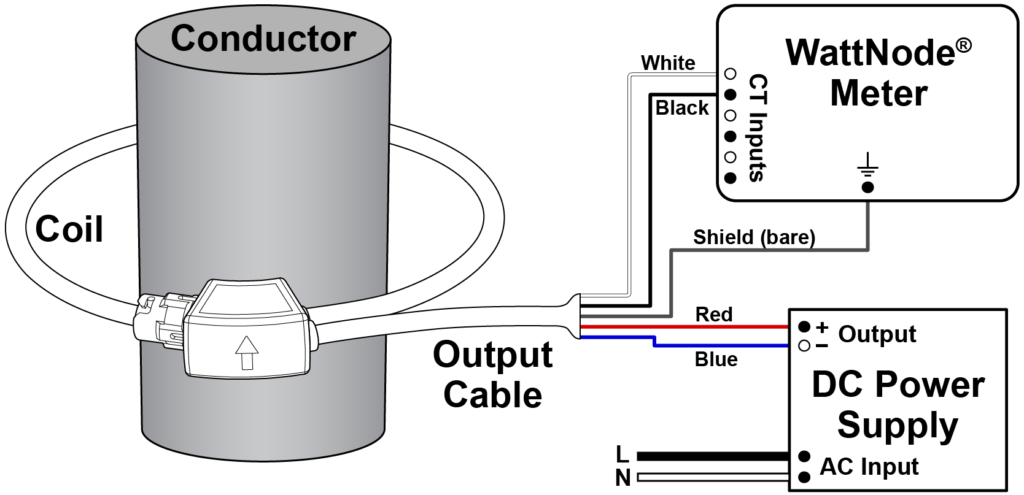

This current sensor is typically made suing a flexible coil of wire wound around a cylindrical core. The wire used is usually a flexible and thin insulated conductor such as copper or aluminum, the coil is wound in helical fashion around the core. For the safety purpose outer material like plastic or non-magnetic metals are uses.

This sensor can measure up to thousands of amps AC without physically connect to live wire using faraday law.

Construction Process of Rogowski coil

As we know construction process is quite simple first involve the winding-

The wire around the core with a specific number of turns to achieve the desired sensitivity and accuracy for current measurement. The wire ends are connected to terminals or a connector for easy integration into a circuit or measurement systems.

The flexibility makes this coil ideal for measuring current in various application includes power systems, electrical machinery and industrial equipment’s.

How to design a Rogowski coil

Designing a Rogowski coil involves several important steps. First, you need to figure out what the coil needs to do, like how much current it should measure and how fast it should respond also how accurate it needs to be

For designing a Rogowski coil following steps are very helpful so lets understands one by one

Step 1: pick a good material for the coil’s core by considering things like how often the current change and how strong it is. Common core material for this coil includes ferrite and powered iron.

Step 2: figure out how many loops the coil needs based on how sensitive want it to be and the core material’s properties. More loop usually means it’s more sensitive but might not work as well fast changes in current.

Step 3: choose a wire that’s the right size for winding the coil. The wire should fit all the loops and have low resistance so the signal doesn’t get weaker as it travels through the wire.

Step 4: wind the wire around the core in a precious manner. Make sure the loops are evenly spaced and tightly wound. This is important to get accurate measurement of the current.

Step 5: connect the ends of the coil to a circuit that can turn the coil’s voltage into a signal you can measure. This circuit might use a resistance or integrator.

Step 6: after assembling the coil, calibrate it using a known current source to check if it measures accurately. Test the coil at different frequencies to see how well it works.

Consider adding shielding to protect the coil from outside magnetic fields. Also, mount the coil securely in the measurement setup to keep it stable and accurate.

Rogowski coil sensor family and series

The LEM Rogowski series offer high accuracy, wide frequency response and easy installation.

Here are family and series of the Rogowski coil

| Series | Description |

|---|---|

| Advanced Rogowski Technology (ART) | Enhances accuracy, linearity and dynamic range so measurements in noisy environments. |

| Analog Rogowski Integrator unit (ARU) | Converts output signal from coil into a usable form for measurement instruments or systems. |

| Integrator | Circuit or device that integrates output signal from coil over time for accurate current measurement. |

These series play key role in improving the performance, accuracy and usability for this current sensor in various electrical measurement applications.

Rogowski coil integrator

An integrator is an important part used with a Rogowski coil in electrical measurements. The coil gives an output voltage that depends on how fast the current changes.

So, an integrator is used to change the coil’s output voltage into signal that show the actual current pattern accurately. When the output voltage of the Rogowski coil is integrated, it shows the original current pattern that give a clear idea and more accurate picture of the current in the conductor being measured.

A Rogowski coil active integrator and a passive integrator these are two different ways to process the output signal of a Rogowski coil current sensor.

Active integrator

The active integrator uses an operational amplifier to generate the output voltage of the coil and creates an output signal that shows the integrates current waveform. This method needs external power for the operational amplifier to work.

Passive integrator

The passive integrator uses simple components like resistors and capacitors to integrate the coil output signal. Unlike the active integrator the passive integrator doesn’t need external power so, it relies only on the characteristics of these basic components to do the integration.

Both integration methods are used to change the transient voltage signal produces by the Rogowski coil into a useful representation of the current waveform.

Rogowski coil formula

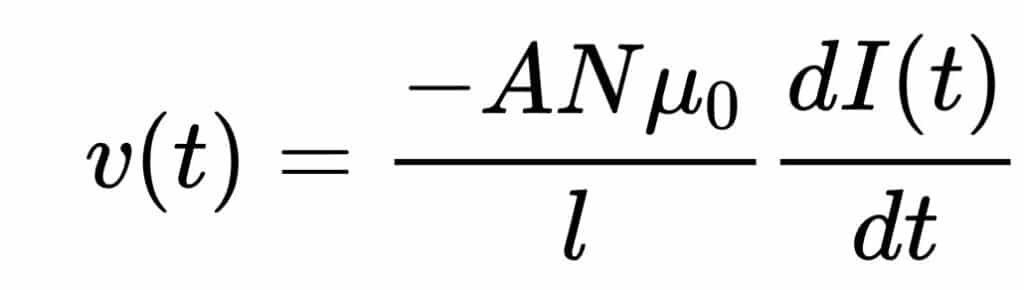

The voltage generated by Rogowski coil can be expressed using the following equations:

Where;

A represents the area of one of the small loops that calculates as π X r^2

N is the number of turns in the coil.

L is the length of the winding that determined by 2 where R is the major radius of the toroid.

denotes the rate of change of current within the loop.

µ0 stand for the magnetic constant, approximately equal to 4 X 10-7 V.s/(A.m).

this formula shows the voltage output of the coil is depends on factors such as the coil’s geometry (area and length) also the number of turns, the rate of change of current and the magnetic constant.

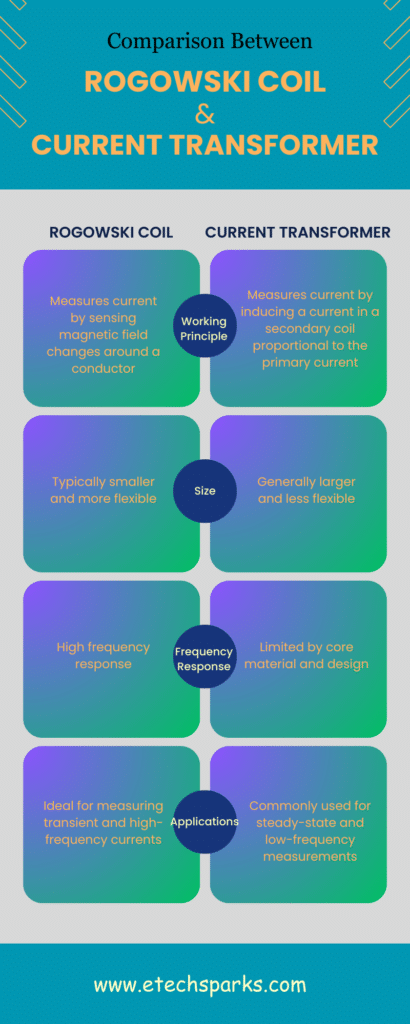

Rogowski coil Vs Current transformer

Let’s make a quick comparison in current transformer and Rogowski coil

Advantages of Rogowski coil

Rogowski coil have several benefits compared to traditional current transformer (CTs) in electrical applications:

- Wide frequency range:

This coil can measure a broad range of frequencies from low to high that make them suitable for various task like power quality monitoring and transient analysis.

- Flexible design:

They have bendable and can be easily wrapped around unevenly shaped conductors or busbars that provide more versatility in installation and usage.

- No core saturation:

They don’t face issue like core saturation and ensuring accurate measurements even at high current.

- High accuracy:

Rogowski coil offer precise measurements, especially in dynamic conditions.

- Isolation:

They provide electrical isolation for safety.

- Compact and lightweight

- Low burden

Disadvantages of Rogowski coil

Some disadvantages like as –

- External interference:

They can be affected by outside electromagnetic signals, which might affect measurement accuracy in noise areas.

- Signal conditioning:

They often need additional circuitry to convert their output into usable current readings that adding complexity and more cost.

- Temperature sensitivity:

Their performance can change with temperature, requiring careful calibration in varying temperature.

Consider these factors is important when deciding to use Rogowski coil for current measurement tasks.

Applications of Rogowski coil

Here are some major applications such as-

- Power quality monitoring:

Used for analyzing electrical parameter like current harmonic and voltage fluctuation.

- Energy management:

Monitors energy consumption to optimize usage and improve efficiency.

- Faulty detection:

Detects electrical faults such as short circuits and overloads for systems reliability.

- Motor current monitoring:

Measures current in motors for protection and performance optimization.

- Electrical vehicle charging:

Ensure safe and efficient charging of electric vehicle by measuring charging current.

- Renewable energy systems:

Monitors current flow in solar and wind power systems for optimal power generation.

- Industrial automation:

Controls electrical; parameter in machinery and processes for improved efficiency and safety.

Frequently asked question

Q. What is the maximum current in Rogowski coil?

Ans: 5,000 amps AC current can handle by this coil and this coil available in five diameters with current rating from 200 to 5,000 amps up to 600 volts.

Q. How to choose Rogowski coil?

Ans: when choosing a Rogowski coil, consider these factors:

- Current rating: pick one that can measure the current you need.

- Accuracy: check how precise it is your needs.

- Size and flexibility: choose a coil that fits and is easy to install.

- Frequency response: make sure it works well with your AC frequency.

- Voltage rating: ensure it can handle your system’s voltage.

- Environmental conditions: consider where it will be used, like temperature and humidity.

- Calibration and certification: check if it’s calibrated and certified for accuracy.

Q. Rogowski coil applications in clamp meter

Ans: Rogowski coils are commonly used in clamp measure for measuring AC currents in electrical circuits. They provide a non-invasive method for current measurement so it allows the clamp meters to accurately measure current without need to break or interrupt the circuit.

This makes them particularly useful for troubleshooting and maintenance tasks in various industries such as electrical engineering, HVAC systems and industrial equipment maintenance.

Q. What is the diameter of a Rogowski coil?

Ans: this coil can come in diameters of 3.1, 4.5 7.5 or 12 inches.

Q. Rogowski coil testing

Ans: testing the coil includes checking for damages, measuring resistance and verifying calibration, testing with know current, checking insulation and assessing environmental durability for accuracy and reliability.

Image credits:

- Rogowski coil structural diagram- accuenergy.com

- Rogowski coil integrator diagram- Wikipedia

- Construction process of Rogowski coil- ctlsys.com

Summery

A Rogowski coil is a type of electrical device used to measure alternating current (AC) in electrical circuit.it is made up of a wire coil wrapped around a core that is not magnetic.

When AC current flows through the conductor being measured. It includes a voltage in the Rogowski coil, which can then be measured and used to determine the magnetic and phase of the current. They offer flexibility, wide range frequency and stability for high-current applications.

Overall, the Rogowski coil offers a non-intrusive and adaptable method for measuring AC currents in various applications including power systems and electric vehicles and industrial machinery.

Nice information explain in simple words and I also got new knowledge about rogowski coil.. thanks for sharing this information.